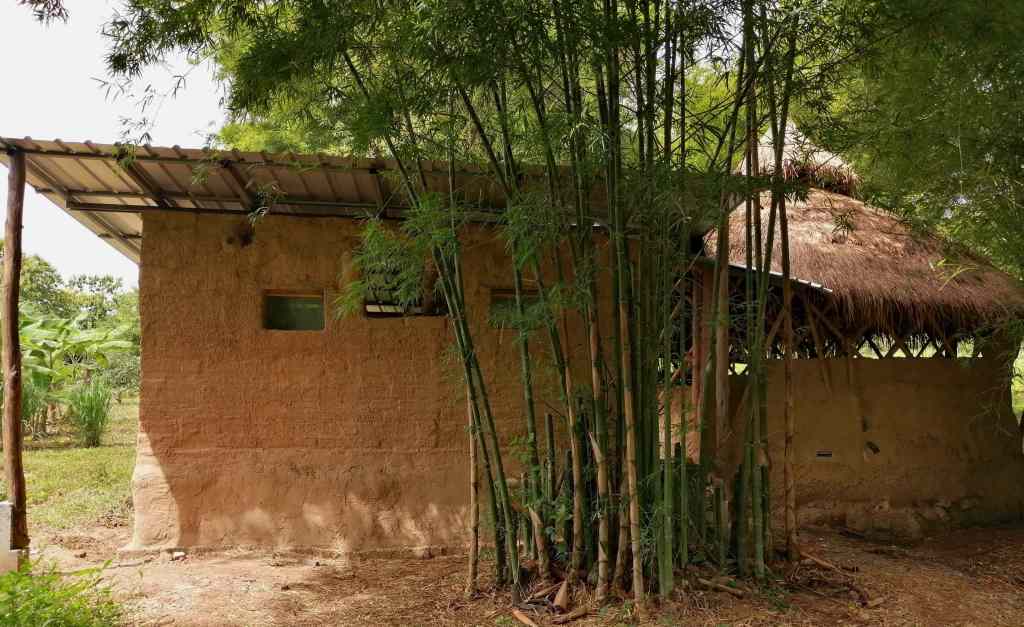

The story… The yurt was built from November 2019 next to the earth bedroom as a round living room and office space. Using local bamboo and soil from the land, its coolness makes it a pleasant room.

We tried to limit the cost wihout affecting the strength, durability, reliability and maintenance by using:

- earth obtained after digging our land to make the walls

- affordable local products (rice straw, rice husk, special grass for thatch roof)

- bamboo canes mostly from our land, were treated against termites

- reclaimed windows

Estimated cost: 60,000 bahts (1,900 USD; 1,600 Euros)

- Materials: 13,000

- Foundation: 2,000 (rubble concrete joined with cement mortar 500 bahts, gravel trench)

- labur: 24,000

- Thatch roof replaced by a conventional material: 21,000 (materials and labour)

The construction

It was installed on a rubble rock foundation to lower expenses and avoid the concrete carbon footprint. Sixty bamboo canes were assembled with strong ropes, treated with non-toxic chemicals (boric acid and borax) to protect them against insects. The roof structure was made of 14 strong treated bamboo poles, and the roof was covered with local thatch, as an insulated and waterproof roof.

The walls are partially covered with earth using a technique adapted from the ancient ‘wattle-and-daub’ technique. Then an earth mix (earth, sand, and straw) is applied around split bamboo weaved between the yurt canes.

Passive cooling

The yurt interior is rather cool most of the time, due to a few elements of the design:

- Large overhang roof

- A few bunches of bamboo around, facing the South and the West

- Earth wall with openings at the top of the walls (cross-ventilation)

- One electric fan inside, useful especially when there is no wind

The thatched roof provided good insulation. It deteriorated after three years, and instead of changing it often, we chose to replace it with a conventional roof.